A Brief History of Modern Supply Chain Management and Best Practices

The topic of supply chain management (and the creation of a coherent set of best practices therein) can be a source of stress. That’s because effective supply chain management is a lot of work.

The practice of supply chain management incorporates myriad concerns – environmental issues, wages as well as health and safety conditions. A varied list, to be sure.

What is the definition of supply chain management?

By way of definition, below is my favourite take on modern supply chain management, courtesy of the Network for Business Sustainability:

“[Supply chain management is the practice of] incorporating a company’s social, environmental and economic goals into the coordination of inter-business processes to improve the long-term economic performance of the individual company and its supply chains.”

The reason I offer this definition versus the multitude a simple Internet search would yield is because of its holistic nature – specifically the social, the environmental and the economic concerns every business should pay attention to when managing its supply chain. Indeed, supply chain management involves all aspects of sourcing, procurement, logistics and production.

For too long those tasked with designing and overseeing supply chains focused too heavily, in some cases solely, on how to squeeze as much profit from the supply chain as possible. Of course, maximizing value and streamlining operations are desirable outcomes, but, as will be discussed throughout the remainder of this paper, prevailing supply chain management is far more complex than a short-sighted, profit-driven exercise (although holistic supply chain management can and will help a company’s revenue).

Today, supply chain management, and the best practices that light the way for practitioners in the field, requires a nuanced understanding of the entire supply chain realm – from the different methodologies available to supplier performance to global regulations to economic concerns.

Yes, it’s hard work – but that is what modern supply chain management requires.

A brief history

Supply chain management, although it may not feel like it to those toiling in the field, is a relatively new concept. One of first instance of the term supply chain management appeared in the early 1980s, in an article of The Financial Times, although it wasn’t until the mid-1990s that the concept gained mainstream recognition.

Though supply chain management cannot yet be considered a “mature” practice, there exists a colorful supply chain history, full of milestones, which contributed to its formation.

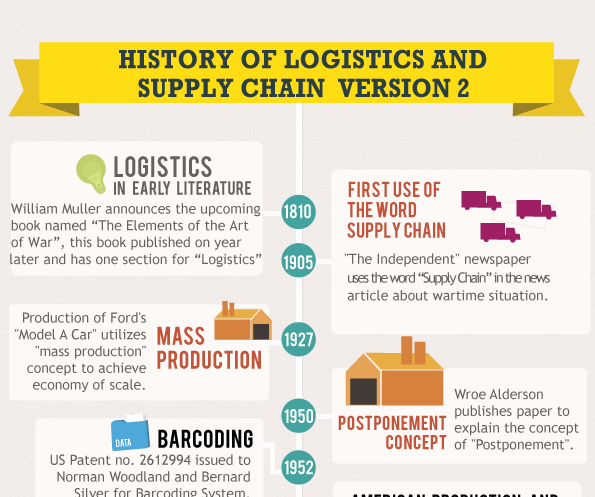

For an excellent visual representation of that history, check out this striking and visual infographic”

Source: Supply Chain Opz

Among the milestones illustrated in the image, for the purposes of this analysis the most important highlights are those that took place within the past three decades.

Creating the Supply Chain Council

Specifically, the first supply chain analysis in 1985, the development of the “total cost of ownership” model in 1995 and the creation of the Supply Chain Council and the Council of Supply Chain Management Professionals in 1996 and 2004 respectively. The tie that binds each of these three examples is the holistic, all-encompassing take they place on supply chain operations.

For example, total cost of ownership is the financial estimate that includes all direct and indirect costs associated with the production of a good. Direct costs reflect those expenses explicitly related to the production of the good in question (i.e. labor costs). Indirect costs, on the other hand, represent costs related to running a business or businesses in a supply chain but not explicitly to the production of a good (i.e. office supplies).

Within the varied umbrella of indirect costs are social costs – potential penalties for human rights violations or environmental damage, to name but two examples. Working with companies in your supply chain that engage in such practices can, and likely will, cost you money thus increasing your total cost of ownership.

Both the professional bodies of the Supply Chain Council (now merged with APICS) and the Council of Supply Chain Management, as well, promote education, communication amongst supply chain partners and the importance of global perspectives as part of their mandates.

The sustainable supply chain

The concept of the sustainable supply chain, just as the definition of supply chain management noted in the introduction, comes courtesy of the Network for Business Sustainability. The theory of the sustainable supply chain meshes so well with modern supply chain management. Ultimately, the sustainable supply chain focuses on environmental and social issues present in the supply chain.

According to the report, “Managing Sustainable Global Supply Chains: Framework and Best Practices,” supply chain issues include (ranked in order of importance):

- Working conditions

- Environmental or green issues

- Corporate social responsibility

- Low wages/minimum wages

- Human rights

- Child labour

- Sustainability

- Health and safety

- Forced/bonded labor

- Sweatshops

- Ethics

- Bribery

- Recycling

- Waste

- Air pollution/emissions

- Water pollution/emissions

- Working hours

*Responses in the survey come from a survey of global supply chain professionals, purchasing managers and corporate executives.*

Morals will impact your bottom line

It wouldn’t (shouldn’t) be a difficult argument to convince both the general public and those in business that the concerns of the sustainable supply chain are correct on moral grounds. But, as we’ve already mentioned briefly, moral issues can have an effect on the bottom line. Modern supply chain management – and supply chain management best practices – is a financial pursuit as well.

For instance, in 1996 Nike faced accusations of child labour in supplier factories. Rightly, in 1998, the pushback was strong enough to force the CEO to announce sweeping changes to the working conditions in those factories.

In 2007, toy giant Mattel recalled US$100 million in product after discovering one of its suppliers used lead paint on its toys. Mattel’s stock price fell 18% as a result.

The emergence of the Chief Financial Officer

Because modern supply chain management best practices and concepts have a significant influence on a company’s revenue, the Chief Financial Officer has a significant role to play in its design and function. That participation, however, does not come at the expense of the principles of modern supply chain management best practices, but works to enhance them.

According to global consulting giant EY (formerly Ernst & Young), there are four key areas of collaboration for the CFO and the supply chain to improve supply chain performance:

- “Creating consistency across the supply chain, the business and the corporate strategy”: those businesses that demonstrate a strong relationship between the CFO and supply chain professionals are more successful aligning their corporate strategy with the supply chain.

- “Supporting and challenging investment choices”: having a CFO involved in the supply chain promotes discussion/debate about expansion and investment, key areas of CFO expertise. Of course, this does not mean that a CFO will stifle supply chain investment; rather, the CFO will help ensure investment is optimized.

- “Monitoring and enhancing performance”: because the CFO is a powerful position, with a profile that spans the entire organization, the CFO is able to help normalize the tools used to measure success of the supply chain.

- “Managing risk and business continuity”: This is a critical area of collaboration – the CFO, often, takes a strong, long-term interest in risk. Modern supply chain management, of course, is keenly focused on minimizing risk in the supply chain by ensuring all suppliers are not engaging in detrimental business practices. With the CFO collaborating with supply chain professionals, the opportunity to define what behavior and practices are too risky is strengthened.

Supply chain best practices

We’ve established the history and what some of the principles of modern supply chain management are. But, naturally, the ultimate goal isn’t simply to define those topics, but to bring those issues to life in your day-to-day business practices.

Such an aim, naturally, is easier said than done, as modern supply chain management is a sweeping, varied concept. As we’ve seen throughout this paper, there are myriad concerns involved in modern supply chain management – so where does one start when attempting to incorporate these practices/beliefs into your organization?

Well, you start at the beginning. To do this right, it requires those in your organization to first set the rules and expectations for your suppliers. After, you need to track those expectations and act upon the performance of those suppliers (either good or bad) should be decided.

According to Infosys, a Seattle-based consulting group, an organization can design an effective set of supply chain management best practices can be designed in seven steps:

- Define your supplier management strategy, including tools and processes (What do we expect of our suppliers?)

- Define the evaluation criteria for supplier performance (How are we going to evaluate those expectations?)

- Collect and analyze performance data (How are our suppliers doing?)

- Measure, report and share the performance data (What does the analyzed data tell us about our suppliers?)

- Conduct meetings for supplier reviews (What should we do with our suppliers?)

- Track and report action points and design improvement plans (How can we improve/tweak our supply chain management best practices?)

- Review and reset goals (What do we expect now of our suppliers?)

Conclusion

Of course, the seven aforementioned steps can be a lot of work. But establishing and enforcing modern supply chain management best practices is worth it.

The demands of today’s supply chain management are both moral and financial – the positive actions of suppliers along the supply chain are critical to the success of any organization. Conversely, involvement with suppliers engaged in unsavory activities – environmental damage, child labor – will reflect poorly on the organization at the top of the chain.

No longer is it good enough to evaluate the supply chain in mere profit-driven terms. Modern supply chain management is a holistic exercise. And that’s a good thing, regardless of how tough that may be to execute.