Efficient Purchase Order Management: Strategies for Faster Procurement

Fast procurement timelines equal happy procurement specialists.

When organizations have organized and efficient purchase order management processes, their procurement teams enjoy:

-

Better supplier terms

-

Faster project turnarounds

-

Improved inventory management

In today’s competitive business environment, effective purchase order management is not just a procedural necessity—it’s a strategic asset. Companies strive to streamline their procurement processes to save time, reduce costs, and enhance operational efficiencies.

This article explores the intricate process of purchase order management, from the initial creation of a purchase order through to its final closure. We’ll uncover the common bottlenecks that can slow down this process and share actionable strategies to overcome these challenges. By implementing best practices and leveraging the right technology, businesses can transform their procurement operations.

Ready to Automate Your Purchasing Process?

Procurify’s procure-to-pay software automates your company’s purchasing workflow from order creation and approvals to invoice payment – to speed up purchasing, improve internal communication, and minimize financial risk.

Understanding purchase order management

Purchase order management is a core component of a business’s procurement strategy, ensuring that all aspects of purchasing are controlled and efficient. It involves overseeing the entire lifecycle of a purchase order (PO) from initiation to fulfillment and closure. This process begins when a company identifies a need for goods or services and ends with the receipt of these goods and the completion of payment. Let’s delve into the essential phases and significance of managing purchase orders effectively.

What is purchase order management?

Purchase order management refers to the systematic process of creating, processing, and managing purchase orders within a company. A purchase order itself is a formal document sent from a buyer to a supplier with a request for products or services. It outlines the types, quantities, and agreed prices for products or services. It is legally binding and serves as a key document in legal and financial accountability and inventory management.

Understanding the purchase order management process

-

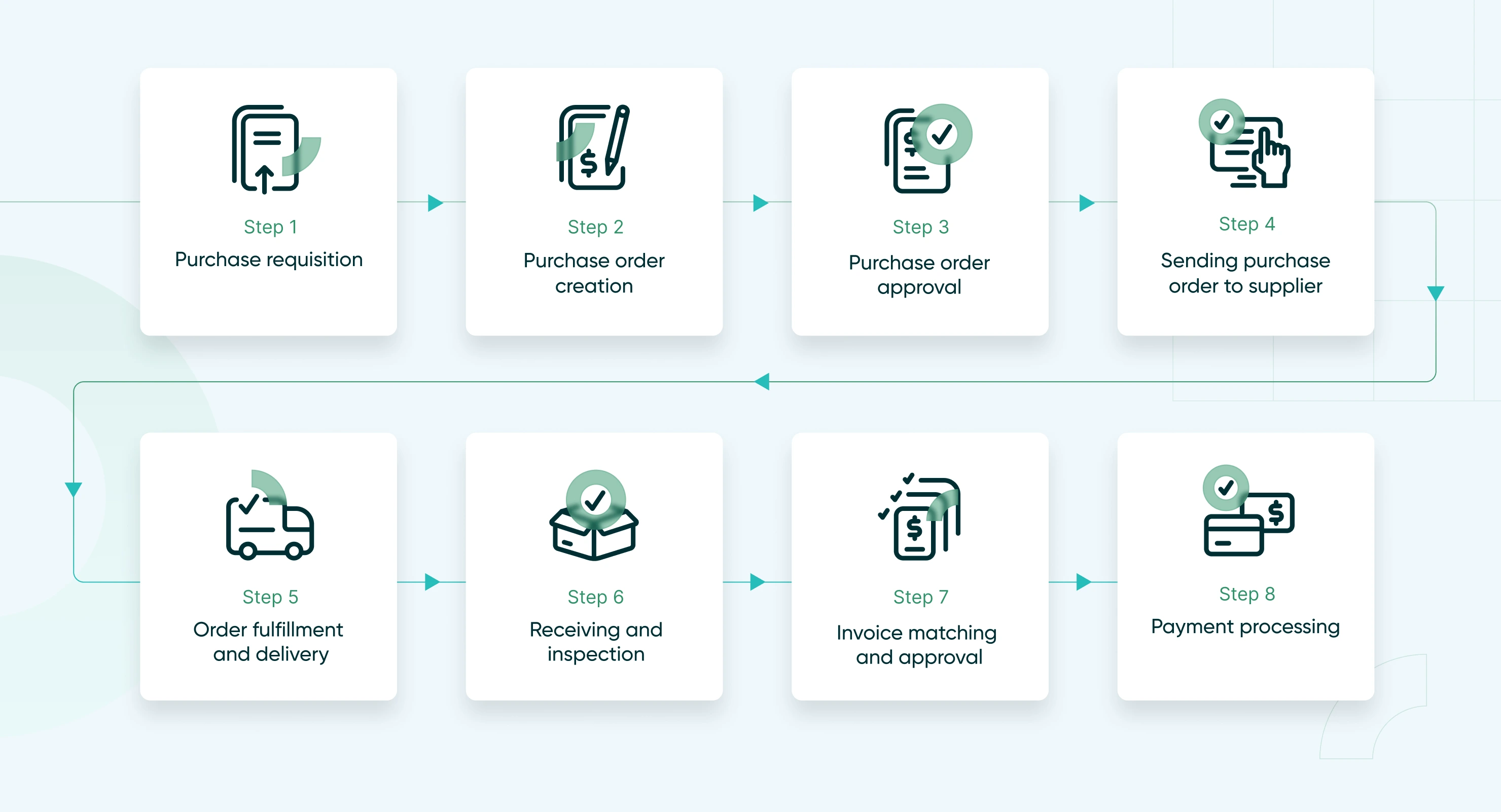

Purchase requisition: The process starts with a purchase requisition made internally within a company, specifying the need for goods or services.

-

Approval and PO creation: Once approved, this requisition leads to the creation of a purchase order, detailing the order specifics such as quantity, type, and price.

-

PO dispatch: The purchase order is then sent to the supplier.

-

Order confirmation and fulfillment: The supplier confirms receipt of the order and, upon agreement of terms, fulfills the order by delivering the specified goods or services.

-

Receipt and inspection: Upon receiving the order, the company inspects the delivered goods or services for quality and accuracy.

-

Invoice receiving and payment: The supplier sends an invoice, which is matched with the PO and the goods receipt note for verification before payment is processed.

-

Record keeping and closure: After payment, the transaction is recorded for financial and audit purposes, and the purchase order is closed out in the system.

Significance of efficient purchase order management

Effective management of purchase orders is crucial for several reasons:

-

Financial control: It helps manage company spend and budgeting accurately.

-

Operational efficiency: Streamlines purchasing processes, reduces errors, and saves time.

-

Compliance and record-keeping: Ensures compliance with company policies and provides audit trails.

-

Supplier relationship management: Improves communication and negotiations with suppliers, leading to better pricing and terms.

This foundational understanding sets the stage for exploring how businesses can speed up their procurement timelines while maintaining accuracy and efficiency in their purchase order processes.

Common challenges in purchase order management

Despite its crucial role in business operations, purchase order management often encounters several challenges that can impede efficiency and effectiveness. Recognizing and addressing these issues is vital to speeding up the procurement timeline and enhancing overall procurement strategy. Let’s explore some of the most common bottlenecks and their implications.

-

Manual processes and paperwork

Many organizations still rely on manual systems for managing purchase orders, which involves extensive paperwork and physical documentation. This reliance on manual entry not only slows down the process but also increases the likelihood of errors—mistakes in order quantities, specifications, or supplier details can lead to significant delays and financial discrepancies.

-

Inefficient approval workflows

Approval bottlenecks are a significant hurdle in many purchase order systems. In cases where multiple approvals are required, the process can stall at any point if approvers are unavailable or if the approval criteria are not clearly defined. This can delay the entire procurement cycle, affecting project timelines and operational efficiency.

-

Lack of integration across systems

A disjointed procurement system, where purchase order management software is not integrated with other business systems such as inventory management, accounting, or ERP systems, can lead to inconsistencies and communication gaps. Without seamless integration, tracking order status, inventory levels, and financial commitments becomes cumbersome and prone to errors.

-

Poor supplier communication

Effective communication with suppliers is essential for managing lead times and ensuring timely delivery of goods and services. Poor communication can result in misunderstandings regarding order specifications or delivery schedules, which can cause delays and affect business operations.

-

Inadequate data tracking and analysis

Tracking and analyzing purchase order data is crucial for identifying inefficiencies and improvement opportunities. However, without the tools to effectively capture and analyze this data, organizations may struggle to understand their procurement patterns, forecast needs, or evaluate supplier performance effectively.

Solutions to overcome challenges

To address these challenges, organizations can adopt several strategies:

-

Automate and digitize: Implementing automated purchase order systems can reduce manual input, minimize errors, and speed up the approval process.

-

Streamline approvals: Simplifying approval workflows with clear guidelines and using digital tools that allow for mobile approvals can ensure that purchase orders are processed swiftly even when key approvers are out of the office.

-

Enhance system integration: Integrating purchase order management software with other business systems ensures that all data is synchronized and accessible, reducing delays and discrepancies.

-

Improve supplier relations: Establishing strong communication channels and regular interactions with suppliers can help in managing expectations and resolving issues promptly.

-

Leverage analytics: Investing in systems that offer robust analytics and reporting features can provide valuable insights into purchasing trends, supplier reliability, and cost-saving opportunities.

By tackling these common issues, businesses can significantly enhance their purchase order management processes, leading to faster procurement cycles and improved operational efficiency.

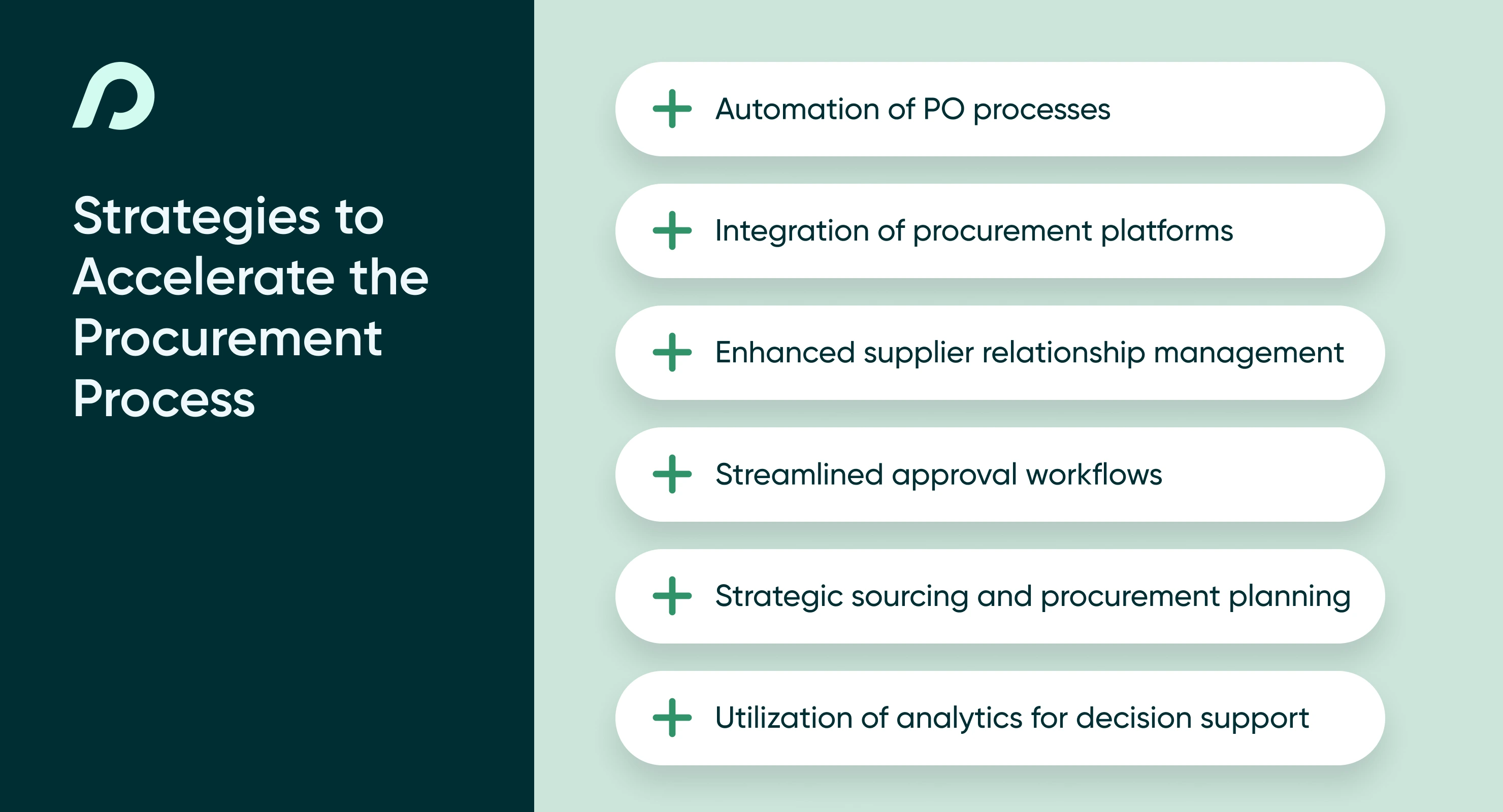

Strategies to accelerate the procurement process

Accelerating the procurement process requires strategic planning and the implementation of efficient systems and practices. By focusing on key areas such as automation, integration, and effective supplier management, organizations can significantly reduce the time it takes from purchase order creation to final payment. Here are some pivotal strategies that can help streamline procurement operations:

Automation of purchase order processes

Automation is one of the most effective ways to speed up the procurement timeline. Automated purchase order management systems can handle many of the manual tasks involved in the procurement process, such as generating purchase orders, sending them to suppliers, and matching invoices to purchase orders upon delivery.

Automation reduces manual errors, cuts down processing time, and ensures compliance with procurement policies. It also allows for faster approvals through electronic workflows that don’t require physical presence, thereby speeding up the entire process.

Integration of procurement platforms

Integrating your purchase order management system with other business systems (ERP, CRM, inventory management) creates a seamless flow of information across all departments. This integration ensures that data is consistent and accessible, which is crucial for quick decision-making and efficient management of resources.

Real-time data updates help track the status of orders and inventory levels, manage financial commitments, and enhance communication between procurement, accounting, and inventory management teams.

Enhanced supplier relationship management

Building strong, reliable relationships with suppliers can dramatically improve procurement efficiency. By negotiating better terms and maintaining open lines of communication, companies can ensure timely deliveries and potentially receive prioritized service.

Effective supplier management helps in negotiating better prices, improving product quality, and reducing lead times. Regular interaction with suppliers ensures that any potential issues are quickly addressed, preventing delays.

Streamlined approval workflows

Streamlining approval workflows by setting clear criteria for purchase order approvals and utilizing digital tools can eliminate unnecessary delays in the procurement process. Tools that support mobile approvals and real-time notifications can keep the process moving even when key approvers are out of office.

A streamlined approval process reduces bottlenecks, improves response times, and increases overall process efficiency.

Strategic sourcing and procurement planning

Strategic sourcing involves analyzing procurement data to make informed decisions about where to buy goods and services and how to manage supplier relationships. Procurement planning ensures that the needs of the business are met in a timely, cost-effective manner without rush-ordering or paying premium prices.

Effective sourcing and planning can reduce costs, improve product quality, and ensure the availability of necessary materials, thereby preventing project delays and optimizing the supply chain.

Utilization of analytics for decision support

Implementing analytics tools within purchase order systems can provide critical insights into procurement operations, helping identify trends, bottlenecks, and opportunities for improvement.

Analytics support strategic decisions, enhance forecasting accuracy, and provide actionable insights that can lead to further optimizations in the procurement process.

By adopting these strategies, businesses can significantly reduce the duration of their procurement cycles, from planning through to execution, ensuring that they not only save time but also enhance operational efficiencies and maintaina a competitive edge in their respective markets.

Choosing the right tools: Purchase order management software

Selecting the appropriate purchase order management software is crucial for optimizing procurement processes. This software automates routine tasks and provides critical insights and enhances communication between departments and suppliers. Let’s discuss key considerations when choosing the right software and highlight some top recommendations.

Key considerations for selecting purchase order management software

-

Integration capabilities: The software should easily integrate with your existing systems such as ERP, accounting software, and inventory management systems. Seamless integration ensures that data flows freely between systems, enhancing visibility and control over the entire procurement process.

-

Scalability: As your business grows, so will your procurement needs. Choose software that can scale with your business, accommodating more users, processing more orders, and managing increased data volume without performance issues.

-

User interface and usability: The software should have a user-friendly interface that simplifies the complexities of purchase order management. Easy navigation and intuitive controls are crucial for ensuring all team members can effectively use the tool.

-

Customization: Every business has unique needs based on its industry, size, and operational requirements. The software you choose should offer customization options that let you tailor features to fit your specific processes.

-

Support and customer service: Reliable customer support is essential, especially when deploying new software. Ensure the vendor offers comprehensive support via multiple channels and provides sufficient training resources.

-

Security: Given the sensitive nature of procurement data, robust security features are non-negotiable. Look for software that offers secure data storage, encryption, and compliance with industry standards.

By carefully considering these factors, investment in the right technology will pay dividends in streamlined operations, improved efficiency, and ultimately, cost savings.

FAQs

Conclusion

Effective purchase order management is pivotal for any business aiming to streamline its procurement processes, enhance operational efficiencies, and optimize cost management. Addressing common challenges, implementing strategic improvements, and utilizing the right tools are key steps toward achieving a faster and more efficient procurement cycle.

For businesses looking to maintain a competitive advantage, refining their purchase order management involves continuous improvement and adaptation to changing business environments and technologies. Investing in the right software, training staff to use new tools effectively, and regularly reviewing procurement processes are essential steps in this journey. By doing so, businesses can accelerate their procurement processes and achieve substantial cost savings and improved supplier relationships, ultimately contributing to greater business success.

Webinar: 5 Strategies for Cost Reduction and Value Creation

Learn how best-in-class procurement leaders are leveraging the right technology to streamline operations, reduce costs, and improve the effectiveness of their purchasing.